- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 12-03-2024 Origin: Site

In the realm of laser technology, particularly concerning the selection of laser cleaning equipment, the terms "single-mode" and "multi-mode" often perplex many individuals.

However, fret not, as Abedar Laser's technical team is here to shed light on the matter.

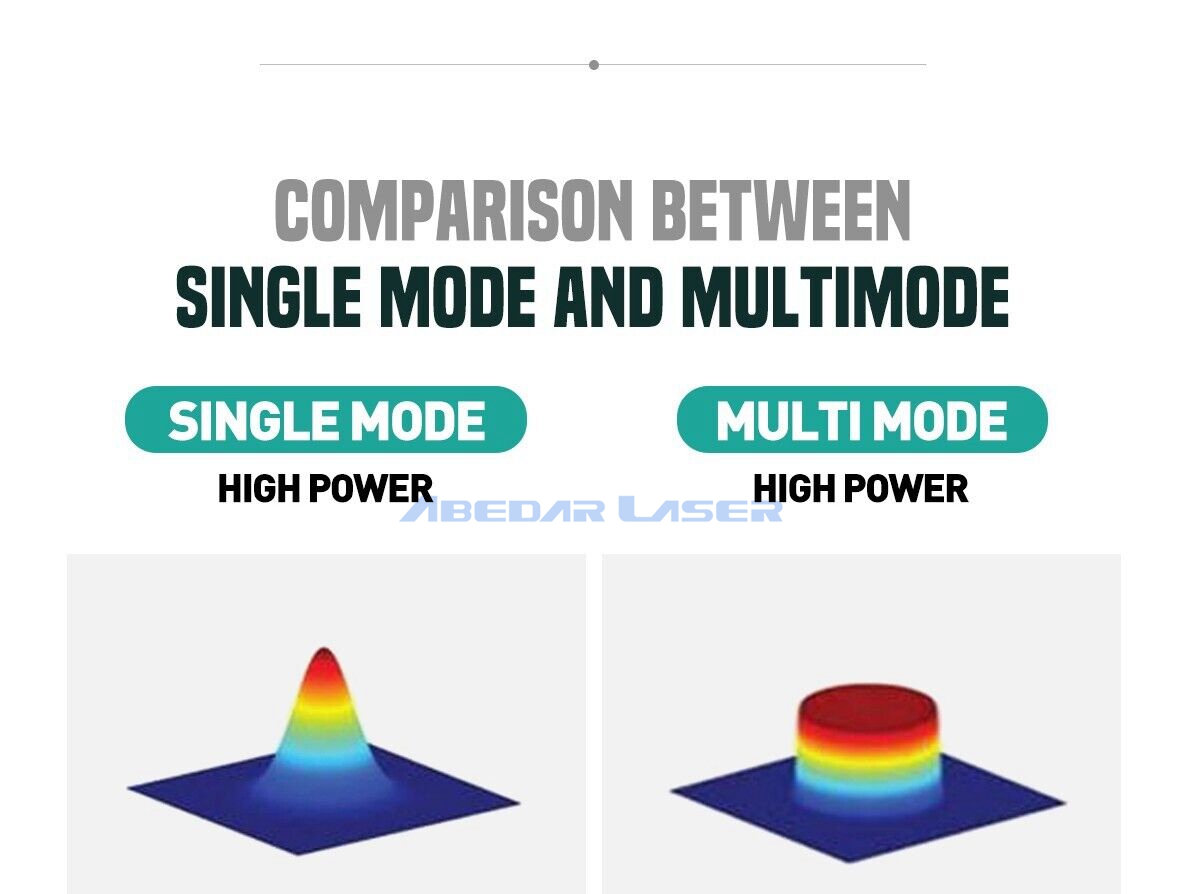

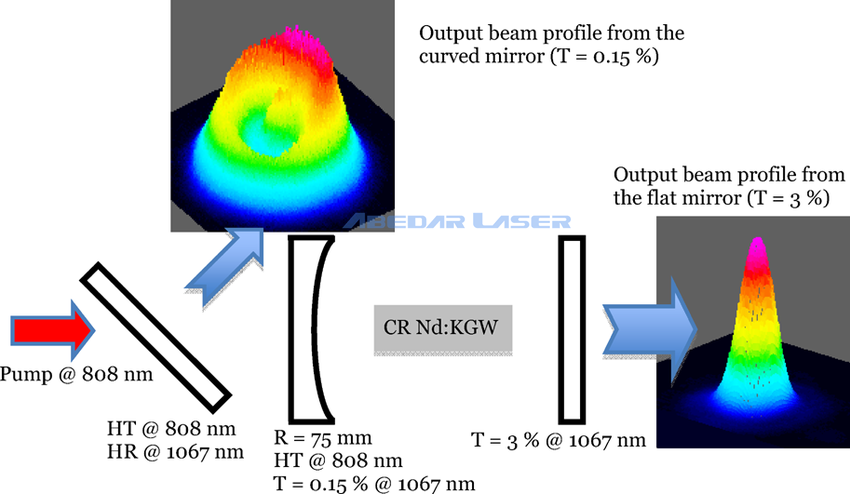

Let's establish some definitions. Single-mode and multi-mode, in the context of lasers, refer to the types of modes the laser operates in. Within a laser device, the propagation of the laser beam can either adhere to a single mode or be a mixture of multiple modes. Fiber laser cleaning machine with a single propagation mode is aptly termed a single-mode laser, whereas a laser supporting multiple propagation modes is dubbed a multi-mode laser. In a single-mode laser, only one mode of beam propagation exists, resulting in a Gaussian distribution of beam diameter and energy. Conversely, a multi-mode laser supports various propagation modes simultaneously, leading to a beam diameter and energy distribution resembling the superposition of multiple wave packets, akin to a flat-top beam.

Now, why does this matter in the realm of laser cleaning, especially when dealing with precision workpieces? The disparity between Gaussian and flat-top beams holds paramount significance. Gaussian beams exhibit a distribution akin to the normal curve, with stronger energy at the center and weaker energy at the edges, rendering their spot unevenly distributed. While Gaussian beams concentrate energy efficiently and can transmit over longer distances, they pose a risk of damaging the substrate material due to their uneven distribution. On the flip side, flat-top beams, as the name suggests, offer a more uniform distribution across the spot. This uniformity proves advantageous when delicately removing contaminants from precision instruments without harming the substrate material.

In the realm of laser cleaning equipment, fiber lasers reign supreme, with two primary variants: pulsed fiber lasers and continuous fiber lasers. Typically, continuous fiber lasers are employed for laser rust removal, whereas pulsed fiber lasers find their niche in cleaning molds. When it comes to the distinction between single-mode and multi-mode in practical applications like handheld laser rust removal machines and laser paint removal tools, the choice becomes clearer.

For instance, handheld laser paint removal tools predominantly operate in the single-mode realm, ensuring precise and efficient removal of paint layers. On the other hand, laser rust removal machines, especially those handheld variants, leverage the benefits of single-mode lasers for meticulous rust eradication without causing substantial damage to the substrate metal.

The primary disparity between single-mode and multi-mode lasers lies in their beam profiles – Gaussian for single-mode and flat-top for multi-mode.

Consequently, their utility varies depending on the application, whether it involves cleaning contaminants or demanding pristine substrate preservation.

In the world of laser technology, understanding the nuances between single-mode and multi-mode lasers equips professionals with the knowledge to make informed decisions tailored to their specific needs.

Abedar Laser's expertise has got you covered,Contact Us Today!